Amid China's rapid transportation infrastructure development, tunnels have become vital components of the national transport network—key projects that traverse mountainous terrain and rivers, connecting regional economies. From highway tunnels cutting through steep mountain ranges to railway tunnels spanning deep, wide rivers, and even undersea tunnels challenging vast oceans, these engineering marvels face formidable challenges from nature. Complex and variable geological conditions, coupled with sudden geological hazards, constantly threaten the safety and efficiency of tunnel construction. Sichuan Drill God Intelligent Machinery Manufacturing Co., Ltd. (hereinafter referred to as “Drill God Intelligent”) has established a robust safety barrier for tunnel construction through its independently developed Drill God DH180 multi-functional drilling rig, becoming an indispensable and capable partner in China's tunnel construction sector.

Tunnel Construction: Seeking Breakthroughs Amidst Geological Challenges

Tunnel construction is akin to a “game of wits” against nature. During underground space development, construction teams frequently encounter “obstacles” from various adverse geological conditions: fractured zones often compromise rock stability, increasing the risk of cave-ins; karst terrain conceals caverns and underground rivers that may trigger mud bursts or water inrushes; in coal-bearing strata and gas-rich environments, the slightest oversight risks gas outbursts; high ground stress and significant deformation in soft rock exert constant pressure on tunnel structures, easily causing support failure; and the presence of shale gas introduces further uncertainties to construction safety. These complex geological conditions intertwine, compounded by the threat of sudden geological hazards like collapses, subsidence, and rock bursts, making safe tunnel construction an extremely challenging systematic endeavor.

In traditional tunnel construction, limitations in geological survey technology often prevent construction teams from comprehensively and accurately grasping the geological conditions ahead of the tunnel face, frequently leaving them in a situation akin to “feeling their way across a river by touching the stones.” When safety incidents occur due to unclear geological information, they not only cause significant economic losses but also endanger the lives of construction personnel. Such incidents can even delay project schedules, impacting the progress of the entire transportation initiative. Therefore, how to proactively identify geological conditions and effectively mitigate construction risks has become a core issue requiring urgent resolution in the tunnel construction field.

Drill God DH180 Multi-Function Drilling Rig: The “All-Round Guardian” for Tunnel Construction

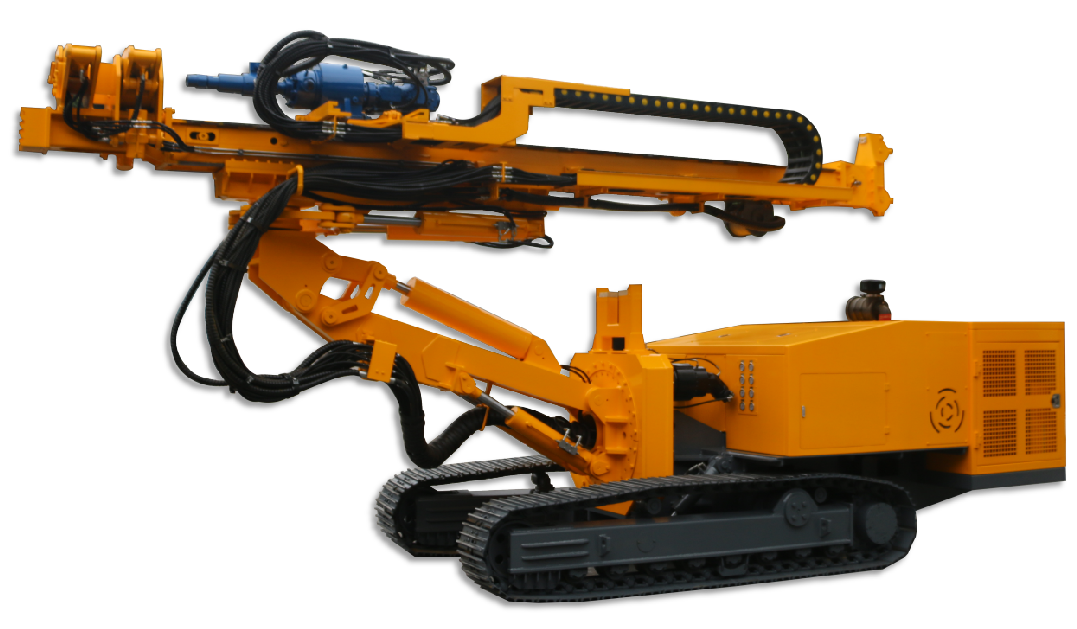

Facing the formidable challenges of tunnel construction, Drill God Intelligent has dedicated years to deepening its industry expertise. Leveraging profound insights into tunnel construction requirements and continuous technological innovation, the company has developed the Drill God DH180 Multi-Function Drilling Rig. This drill integrates multiple construction functions—including advance tunneling, core sampling, and advance support—into one unit. It not only excels in core applications like tunnel geological forecasting and ground improvement but also extends its utility to construction sectors such as foundation pit support, anchor rod and cable installation in construction, as well as emergency scenarios like drainage drilling, venting drilling, and lifeline drilling in rescue operations. It truly achieves “one machine for multiple uses, comprehensive coverage,” providing all-around technical support for tunnel construction and related fields.

Powerhouse Performance: The “Core Engine” Conquering Complex Geology

The core strength of the Drill God DH180 multi-functional drill lies in its robust power system. Equipped with a high-torque, high-speed hydraulic percussion and rotary drilling power head, it effortlessly handles resistance from deep-hole and large-diameter drilling, as well as complex geological conditions like loose formations. In tunnel construction, whether performing advance drilling in deep geological layers, meeting stringent precision and efficiency demands for large pipe arch installations, or executing hollow anchor rod drilling operations, the Drill God DH180 delivers high-efficiency drilling through its exceptional power performance, significantly boosting construction efficiency. Compared to traditional rigs, its power system offers superior stability and adaptability. Even in challenging geological environments like fractured zones and soft rock, it maintains consistent drilling performance, saving construction teams substantial time and labor costs.

Intelligent Monitoring: The “Eagle Eye” for Geological Insight

To help construction teams anticipate geological conditions ahead of the drill face, the Drill God DH180 multifunctional rig incorporates intelligent monitoring technology. Equipped with multiple high-precision sensors and flow meters, it collects real-time critical drilling data, including 12 core parameters: drilling depth, drilling speed, rotational speed, torque, rotational pressure, impact energy, impact count, impact pressure, thrust force, water supply volume, drainage volume, water supply pressure, and drainage pressure. This data undergoes analysis and interpretation through a dedicated processing system, enabling precise assessment of ground conditions ahead of the tunnel face: variations in drilling speed and torque indicate rock hardness; discrepancies between water supply and drainage volumes monitor water inflow risks; abnormal fluctuations in drilling resistance detect cavities (karst voids).

This “data-driven” geological monitoring approach fundamentally overcomes the limitations of traditional geological surveys, enabling the visualization of tunnel geological environments. Construction teams no longer need to wait until excavation begins to discover geological issues. Instead, they can obtain detailed geological information during the drilling phase, providing scientific basis for formulating and adjusting construction plans. This approach reduces the risk of safety incidents caused by unclear geological surveys at the source.

Advanced Early Warning: The “Safety Barrier” Against Geological Hazards

In tunnel construction, early warning of geological hazards is critical. Through advanced horizontal geological drilling, the Drill God DH180 multi-functional drilling rig comprehensively detects the geological conditions ahead of the excavation face for underground structures (including tunnels, galleries, underground power plants, etc.) before tunnel excavation begins. Construction teams leverage the geological data obtained by the drill rig to gain clear insights into the structure, properties, and condition of the rock and soil ahead, as well as the presence of groundwater, gas, and stress distribution. This enables them to anticipate potential geological hazards such as water inrushes, gas outbursts, rock bursts, and large deformations.

For instance, upon detecting a high-pressure underground river ahead, the construction team can proactively implement measures like drainage to reduce pressure and reinforce support structures. Upon detecting excessive gas concentrations, they can promptly activate ventilation and exhaust systems to eliminate the risk of gas outbursts. Through this “advance detection, early warning, and proactive response” model, the Drill God DH180 multi-functional drill rig establishes a robust safety barrier for tunnel construction, effectively safeguarding workers' lives and ensuring smooth project progress.

Real-World Application: The All-Rounder from Emergency Rescue to Engineering Construction

The exceptional performance of the Zhuanshen DH180 multi-functional drill rig has been thoroughly validated not only in conventional tunnel construction but also in emergency rescue scenarios, where it proves its vital role as a “life-saving tool.” During tunnel collapses, the safety of trapped individuals becomes a matter of utmost urgency. Selecting the optimal rescue location and formulating a scientifically sound rescue plan are critical to ensuring success. Here, the Drill God DH180 plays a pivotal role: through precise drilling operations, it determines the structural characteristics of the collapsed mass and pinpoints the exact location of trapped personnel. simultaneously, its drainage and ventilation drilling capabilities remove accumulated water and hazardous gases from the collapsed structure, creating a safer survival environment for the trapped individuals; most importantly, the drill can rapidly establish a lifeline passage to deliver food, water, and oxygen to the trapped individuals, buying precious time for the rescue operation.

Beyond emergency rescue operations, the Drill God DH180 multi-functional drilling rig also delivers outstanding performance in routine tunnel construction projects. To date, Zhuanshen Intelligent has provided advance geological drilling services for over 30 expressway projects and hundreds of tunnels nationwide. During a highway tunnel project in Yunnan, the tunnel traversed complex karst terrain, encountering multiple mud and water outbursts early in construction, causing significant delays. After introducing the ZuanShen DH180 multi-functional drill rig, the construction team conducted advance drilling to locate 12 karst cavities and underground rivers ahead of the tunnel. They then implemented targeted reinforcement and drainage solutions, which not only completely resolved the mud and water outbursts but also boosted construction efficiency by 30%, ensuring the project was completed three months ahead of schedule. Similar success stories continue to unfold nationwide. Through tangible results, the Zhuanshen DH180 multi-functional drill rig provides effective technical guidance for tunnel construction, helping mitigate project risks.

Drill God Intelligent: Empowering China's Tunnel Construction with Professional Expertise

As a specialized manufacturer of multi-functional drilling rigs, Sichuan Drill God Intelligent Machinery Manufacturing Co., Ltd. has consistently adhered to the philosophy of “technology innovation as the core, customer needs as the guide” since its establishment, deeply cultivating the field of tunnel construction equipment. The company boasts an R&D team of senior engineers and technical experts dedicated to upgrading multi-functional drilling rig technology and product iteration. They have overcome multiple core technical challenges, including high-torque power heads, intelligent data monitoring, and complex geological adaptability, ensuring products maintain industry-leading performance.

In service delivery, Zhuanshen Intelligent adheres to a “one-stop service” philosophy, providing clients with comprehensive support from product consultation and solution design to equipment installation, commissioning, and post-installation maintenance. For each tunnel project's unique geological characteristics and construction requirements, the company dispatches specialized technicians to the site to develop customized drilling solutions. Additionally, a 24-hour emergency response mechanism ensures technicians arrive promptly to resolve equipment issues during operation, safeguarding uninterrupted construction progress.

Through exceptional product quality and superior service, DrillGod Intelligent has earned widespread client recognition, becoming a long-term partner for numerous domestic transportation construction groups and tunnel contractors. Moving forward, DrillGod Intelligent will continue focusing on technical demands within the tunnel construction sector, significantly increasing R&D investment to advance multifunctional drilling rigs toward greater intelligence, efficiency, and safety. The company is committed to contributing more to China's tunnel construction industry, helping build “safe, efficient, and green” tunnel projects that safeguard the development of China's transportation network and regional economies.